Definition

A gravity separator is a pressure vessel used to separate mixed phase streams into gas and liquid. As per the name dictate the separation is controlled by gravitational forces.

How is a gravity separator classified?

Classified by their geometrical configurations as vertical or horizontal separators, they function as two-phase separators if they separate gas from a total liquid stream, and three-phase separators if they separate gas from liquid and liquid into crude oil and water phases.

Gravity separators can be categorized according to their operating pressure as shown in the table below:

| Pressure | kPa | PSI |

|---|---|---|

| Low | 69 to 1241 | 10 to 180 |

| Medium | 1586 to 4826 | 230 to 700 |

| High | 6722 to 10342 | 975 to 1500 |

Main features of a gravity separator

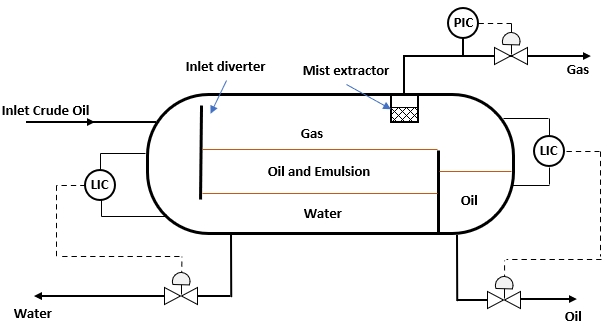

All gravity separators have the following features:

- Gas/liquid separation section with an inlet diverter to remove the bulk of the liquid from the gas. In most designs, the inlet diverter contains a downcomer that directs the liquid flow below the oil/water interface

- Gravity-settling section, this section allows a retention time so that proper settling may take place.

- Mist extractor at the gas outlet to capture entrained droplets or those too small to settle by gravity.

- Pressure and liquid-level controls.

Horizonal Separators

Commonly used when the following conditions are available:

- Three phase separation needed.

- high gas and or liquid volumes.

- High to medium gas to oil ratio (GOR) streams.

- Foaming crudes.

Advantages

- Gas flow does not oppose drainage of mist extractor or no counter flow

- Reduced turbulence due to large liquid surface area for foam dispersion

- Require smaller diameter for similar gas capacity as compared to vertical vessels.

- Larger surge volume capacity

Disadvantages

- Liquid level control is more critical

- Only part of shell available for passage of gas

- Occupies more space or large plot area

- Difficult to clean

Vertical Separators

Commonly used when the following conditions are available:

- Small flow rates of gas and/or liquids

- Very high gas to oil ratio (GOR) streams or when the total gas volumes are low.

- Plot space is limited.

- Ease of level control is desired.

Advantages

- Has full diameter for gas flow at top and oil flow at bottom

- Liquid level control is not so critical

- Have good bottom-drain and clean-out facilities.

- Can handle more sand, mud, paraffin, and wax without plugging

- Less tendency for re-entrainment

- Occupies smaller plot area

Disadvantages

- Not recommended when there is a large slug potential

- Require larger diameter for a given gas capacity, therefore, most competitive for very low GOR or very high GOR or scrubber applications.

- More difficult to reach and service top-mounted instruments and safety devices

Useful reference

Mokhatab S., Poe W. A., Speight J. G., Handbook of natural gas transmission and processing, Gulf Professional Publishing, 2006