Welded Plate Heat Exchangers: Applications, Advantages, Disadvantages, and Thermal Design Methodology

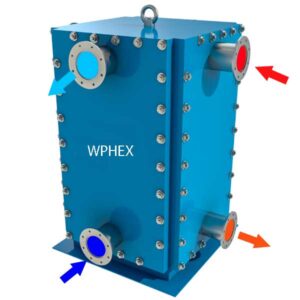

Heat exchangers are essential components in many industrial processes. They are used to transfer heat between two fluids that are at different temperatures, allowing for energy conservation and cost savings. Welded plate heat exchangers (WPHEs) are a type of compact heat exchanger that are gaining popularity in many industries due to their high efficiency and compact design. In this article, we will explore the applications, advantages, disadvantages, and thermal design methodology of WPHEs.

Applications

WPHEs are used in a wide range of industrial applications, including:

- HVAC (heating, ventilation, and air conditioning) systems

- Refrigeration systems

- Food and beverage processing

- Chemical and pharmaceutical processing

- Power generation

- Oil and gas production

Advantages and Disadvantages of welded plate heat exchangers

Advantages

There are several advantages of welded plate heat exchangers over other types of heat exchangers, including:

- Compact Design: WPHEs have a compact design that allows for a high heat transfer rate in a small footprint, making them ideal for applications where space is limited.

- High Efficiency: WPHEs have a high heat transfer efficiency due to their large surface area and turbulent flow, which allows for more efficient heat transfer between the two fluids.

- Corrosion Resistance: WPHEs are made of corrosion-resistant materials, such as stainless steel, which makes them ideal for use in corrosive environments.

- Low Maintenance: WPHEs have no gaskets or seals, which reduces the need for maintenance and minimizes the risk of leaks.

- Customizable Design: WPHEs can be designed to meet specific requirements, such as pressure drop, temperature range, and flow rate, making them highly customizable for different applications.

Disadvantages

There are also some disadvantages to using welded plate heat exchangers, including:

- Higher Initial Cost: WPHEs have a higher initial cost compared to other types of heat exchangers, such as shell and tube heat exchangers.

- Limited Temperature Range: WPHEs are not suitable for high-temperature applications due to their limited temperature range.

- Limited Pressure Range: WPHEs have a limited pressure range compared to other types of heat exchangers.

| Advantages | Disadvantages |

|---|---|

| Compact Design | Higher Initial Cost |

| High Efficiency | Limited Temperature Range |

| Corrosion Resistance | Limited Pressure Range |

| Low Maintenance | |

| Customizable Design |

Thermal Design Methodology

The thermal design of welded plate heat exchangers involves determining the heat transfer rate, pressure drop, and size of the heat exchanger. The design process typically involves the following steps:

- Determining the Heat Transfer Rate: The heat transfer rate is determined based on the fluid flow rates, temperatures, and heat transfer coefficients.

- Determining the Pressure Drop: The pressure drop is calculated based on the fluid properties, flow rates, and heat exchanger geometry.

- Selecting the Plate Material: The plate material is selected based on the fluid properties, temperature, and corrosion resistance requirements.

- Plate Configuration: The plate configuration is selected based on the design parameters and the available plate designs.

- Plate Spacing: The plate spacing is selected based on the fluid properties and the required heat transfer rate.

- Heat Exchanger Sizing: The heat exchanger is sized based on the heat transfer rate, pressure drop, and available space.

Conclusion

Welded plate heat exchangers are an efficient and compact type of heat exchanger that have a wide range of applications in many industries. They offer several advantages over other types of heat exchangers, including high efficiency, compact design, corrosion resistance, low maintenance, and customizable design. However, they also have some disadvantages, such as higher initial cost, limited temperature range, and limited pressure range. The thermal design methodology of WPHEs involves determining the heat transfer rate, pressure drop, and size of the heat exchanger through a series of design steps. Overall, WPHEs offer a promising solution for many industries looking for an efficient and space-saving heat exchanger.

External links

Gasketed plate heat exchanger design (PHex) – size gasketed plate heat exchangers