Definition

Pipeline riser is a very important component in pipeline system. It provides a means of transfer of product between the pipeline on the seabed and the processing equipment on platform. So mainly a pipeline riser is a connection between the platform piping to the subsea pipeline. A pipe that connects hydrocarbon production and transporting facility to a processing equipment on a platform.

Riser system contains pipes connecting floating platforms on the sea surface and the wellheads at the seabed.

Type of pipeline risers

The main types are rigid risers and flexible risers. Hybrid risers which is a combination of the two types.

What are the main functions of a pipeline riser?

Riser system has three basic functions

Production

Production risers connect a reservoir to wellhead equipment on a floating or fixed platform.

Drilling

Drilling risers are used during drilling for oil and gas using a floating or a jack-up drilling rig.

Export and Import or circulate fluids

Export and import risers are a series or pipes that connect an incoming or outgoing pipeline to platform deck piping.

What does a typical pipeline riser system mainly contain?

Typically:

- A rise body or conduit

- Components

- Auxiliary

- Interface with a floater and wellhead

Offshore production facilities can be categorised as shown below:

- Subsea, where a production from a wellhead is generally transported to a receiving platform by a subsea pipeline that is connected to the platform through a pipeline riser.

- Fixed platform includes tubular (jacket) or gravity structures.

- Floating platforms includes semi-submersible, tension-leg platforms, anchored ship or FPSO

Types of Export and Import Pipeline Riser

- Steel pipeline risers on fixed platforms

- Flexible pipeline risers on floating platforms such as FPSO

- Hybrid steel and flexible pipeline risers with floating production systems

- Tensioned steel pipeline risers on tension leg platforms.

Flexible Pipeline Risers Global Configuration

Flexible pipeline risers have different configurations, their design depends on several factors and also Performed based on productions requirements and site environmental conditions. Analysis are normally carried out to determine the correct configuration.

The biases of the analysis to determine a configuration looks into the structural integrity, rigidity and geometry, cross sectional properties, means of support, material and costs.

There are six main configurations for a flexible pipeline riser, these configurations include several factors such as the depth of water, access to vessel, field layout and mooring layout as well as vessel motion characteristics.

Free hanging catenary flexible pipeline riser

- Simple layout and cheap to install

- Doesn’t require too much subsea infrastructure

- High exposure to loading due to vessel motions and can suffer from compression buckling at the riser touch down point

Lazy wave flexible pipeline riser

- Buoyancy and weight are added along a longer length of the riser, to decouple the vessel motions from the touch down point of the riser

- Configuration requires minimal subsea infrastructure

- If the internal pipe fluid density changes during the riser lifetime, configuration alterations is required.

- Buoyancy modules tend to lose buoyancy over time, and wave configurations are inherently designed to accommodate up to a 10% loss of buoyancy

Steep wave

- Buoyancy and weight are added along a longer length of the riser, to decouple the vessel motions from the touch down point of the riser

- More subsea infrastructure required as to Lazy wave configuration

- Need a subsea base and subsea bend stiffener

- Able to maintain their configuration even if the riser fluid density changes

- Buoyancy modules tend to lose buoyancy over time, and wave configurations are inherently designed to accommodate up to a 10% loss of buoyancy

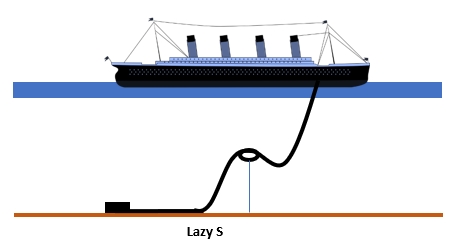

Lazy S

- Configured to have either a fixed subsea buoy, which is fixed to a structure at the seabed or a buoyant buoy which is positioned using chains

- Requires a mid-water arch, tether and tether base

- Complex modelling is required due to the large inertial forces in action

- Compression problems could occur at the riser touchdown in large vessels cases

Steep S

- Configured to have either a fixed subsea buoy, which is fixed to a structure at the seabed or a buoyant buoy which is positioned using chains

- Considered when catenary and wave configurations are not suitable for a particular field due to complex installation requirements

- Requires a buoy and subsea bend stiffener

- Complex modelling is required due to the large inertial forces in action

- Alternative to lazy S if there are any compression problems at the riser touchdown

Pliant wave

- Almost similar to steep wave configuration with an additional benefit that it’s tied back to the well located beneath the floater, this allows well intervention without an additional vessel.

- Able to accommodate a wide range of bore fluid densities and vessel motions without significant change in configuration

- Complex subsea installation requirement, only used if simple catenary, lazy wave or steep wave configurations are not suitable

Reference

Yong Bai, Qiang Bai, Subsea pipelines and risers, 2005, Elsevier