Introduction

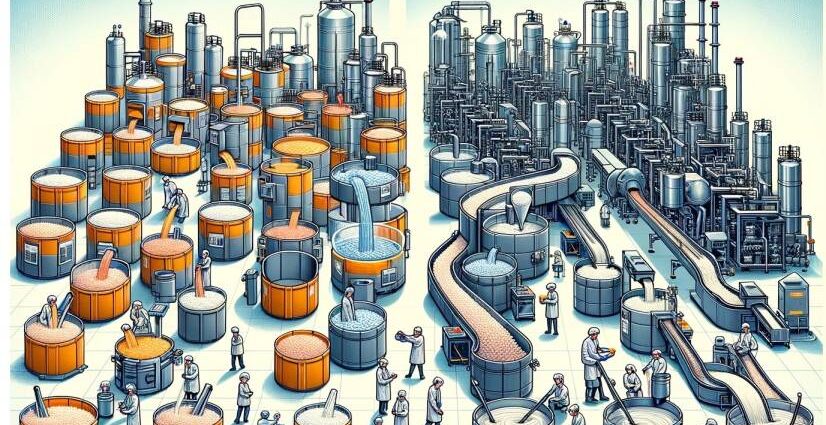

In the world of chemical manufacturing, selecting the right processing approach can have a profound impact on efficiency, productivity, and profitability. Two primary methods stand out: batch processing and continuous processing. Each has its own set of advantages and disadvantages, making the choice between them a critical decision for chemical manufacturers. In this article, we will delve into the key differences and considerations when it comes to “Batch vs Continuous Processing,” helping you make informed decisions for your chemical manufacturing processes.

Understanding Batch Processing

So let’s look at both Batch vs Continuous processing;

What is Batch Processing?

Batch processing is a manufacturing method where a set quantity of raw materials is processed as a single unit or batch. These materials are mixed, reacted, or transformed in a controlled environment until they reach the desired quality or state. Common examples of batch processing in the chemical industry include pharmaceutical manufacturing, food processing, and specialty chemical production.

Advantages of Batch Processing

- Flexibility: Batch processing allows for easy changes in product formulations and process parameters, making it suitable for small-scale or custom production runs.

- Quality Control: Each batch can be closely monitored and adjusted as needed, ensuring consistent product quality.

- Reduced Initial Investment: Setting up batch processes can be less capital-intensive compared to continuous systems.

Disadvantages of Batch Processing

- Time-Consuming: Batch processing often takes longer to complete than continuous processes, resulting in lower throughput.

- Resource Inefficiency: Batch processes may require cleaning and setup between batches, leading to downtime and resource wastage.

Understanding Continuous Processing

What is Continuous Processing?

Continuous processing, as the name suggests, is a method where materials are continuously fed into a production line and transformed without interruption. This approach is characterized by a steady flow of raw materials, with little to no start-stop cycles. Industries like petrochemicals, bulk chemical production, and refineries commonly employ continuous processing.

Advantages of Continuous Processing

- High Throughput: Continuous processes often yield higher production rates, making them suitable for large-scale manufacturing.

- Reduced Labor Costs: Continuous systems require less human intervention, leading to lower labor costs and increased safety.

- Consistent Quality: The steady flow of materials and automated controls contribute to consistent product quality.

Disadvantages of Continuous Processing

- Limited Flexibility: Making changes in product formulations or process parameters can be challenging in continuous systems.

- High Initial Investment: Setting up continuous processes typically requires significant capital investment in equipment and automation.

Choosing Between Batch vs Continuous Processing

Now that we have a clear understanding of both batch and continuous processing, the decision-making process becomes crucial. Here are some factors to consider when choosing the right approach for your chemical manufacturing:

1. Production Volume:

- Batch: Ideal for small to medium production volumes, custom orders, and specialty chemicals.

- Continuous: Suited for large-scale production with high volume requirements.

2. Product Variability:

- Batch: Provides flexibility to accommodate changes in product formulations or recipes.

- Continuous: Best for consistent, standardized products with minimal variations.

3. Efficiency and Throughput:

- Batch: Lower throughput and longer processing times.

- Continuous: Offers higher throughput and shorter processing times, but less flexibility.

4. Capital Investment:

- Batch: Generally requires lower initial capital investment.

- Continuous: Demands higher upfront investment in specialized equipment and automation.

5. Quality Control:

- Batch: Allows for closer monitoring and adjustments to ensure product quality.

- Continuous: Offers consistent quality through automated controls.

6. Regulatory Compliance:

- Batch: May be preferred in industries with strict regulatory requirements, as changes can be made more easily to meet compliance standards.

- Continuous: Requires rigorous validation due to limited process changes.

Conclusion

In the realm of chemical manufacturing, the choice between Batch vs Continuous processing is not a one-size-fits-all decision. It depends on the specific needs of your industry, product, and production volume. Batch processing offers flexibility and lower upfront costs, making it ideal for small-scale or custom production. On the other hand, continuous processing offers higher efficiency, throughput, and consistency, making it suitable for large-scale manufacturing.

Ultimately, the key to success lies in understanding your unique requirements and striking the right balance between the advantages and disadvantages of each approach. Whichever method you choose, careful planning and implementation are essential to maximize productivity and ensure product quality. In the ever-evolving landscape of chemical manufacturing, selecting the right processing approach can make all the difference.

By carefully evaluating the pros and cons of Batch vs Continuous processing, you can make an informed decision that aligns with your business goals and sets the stage for success in the competitive world of chemical manufacturing.

Optimizing your chemical manufacturing process starts with choosing the right approach: batch or continuous processing. Make the right choice today to ensure a more efficient and profitable tomorrow. Hopefully this short article has provided a good outlook in helping when considering Batch vs Continuous processing.

Keywords: Batch vs Continuous processing.

Trending article: Horsepower vs Shaft Horsepower

External Article: Batch Production